Trends and Innovations in the Best Punching Tool Industry for 2025 Insights and Data

As we look ahead to 2025, the punching tool industry is poised for significant transformation driven by emerging trends and innovations. This dynamic sector, integral to manufacturing and construction processes, is witnessing advancements that promise to enhance efficiency, precision, and sustainability. From the incorporation of smart technology and automation to the development of eco-friendly materials, the future of punching tools is brimming with opportunities for growth and improvement. Additionally, emerging market demands and shifting consumer preferences are reshaping the landscape, prompting manufacturers to adopt cutting-edge designs and functionalities. In this blog, we will explore the key trends and innovations that are set to define the punching tool industry in the coming years, providing insights and data that will equip professionals with the knowledge to navigate this evolving arena effectively.

Overview of Key Trends Shaping the Punching Tool Industry by 2025

As we look towards 2025, the punching tool industry is poised for significant transformation driven by several key trends. One notable trend is the increasing automation in manufacturing processes, which is projected to grow by approximately 15% according to a recent report by Markets and Markets. This automation trend not only enhances efficiency but also reduces the operational costs associated with manual labor, allowing manufacturers to allocate resources more effectively.

Another pivotal development is the rise of smart technologies in punching tools. The integration of IoT and AI in tool design and production is set to boost productivity by facilitating real-time monitoring and predictive maintenance. According to a study by Research and Markets, the smart tools segment is expected to reach a valuation of $5 billion by 2025, reflecting a compound annual growth rate (CAGR) of 20%. This shift towards smarter solutions aligns with the industry's broader push for sustainable practices, as energy-efficient models become increasingly favored in the marketplace.

Moreover, the demand for custom and versatile punching tools is on the rise, driven by the expanding applications across various sectors including automotive and aerospace. A Frost & Sullivan report indicates that the customization market for tools could expand by over 10% annually, highlighting the need for manufacturers to adapt to specific customer requirements and evolving industry standards. As these trends continue to shape the landscape, the punching tool industry will undoubtedly evolve, presenting new opportunities and challenges for stakeholders involved.

Trends in the Punching Tool Industry (2025)

This chart illustrates the projected trends and innovations in the punching tool industry for 2025, focusing on market demand across various applications.

Innovative Technologies Revolutionizing Punching Tools: A Comprehensive Review

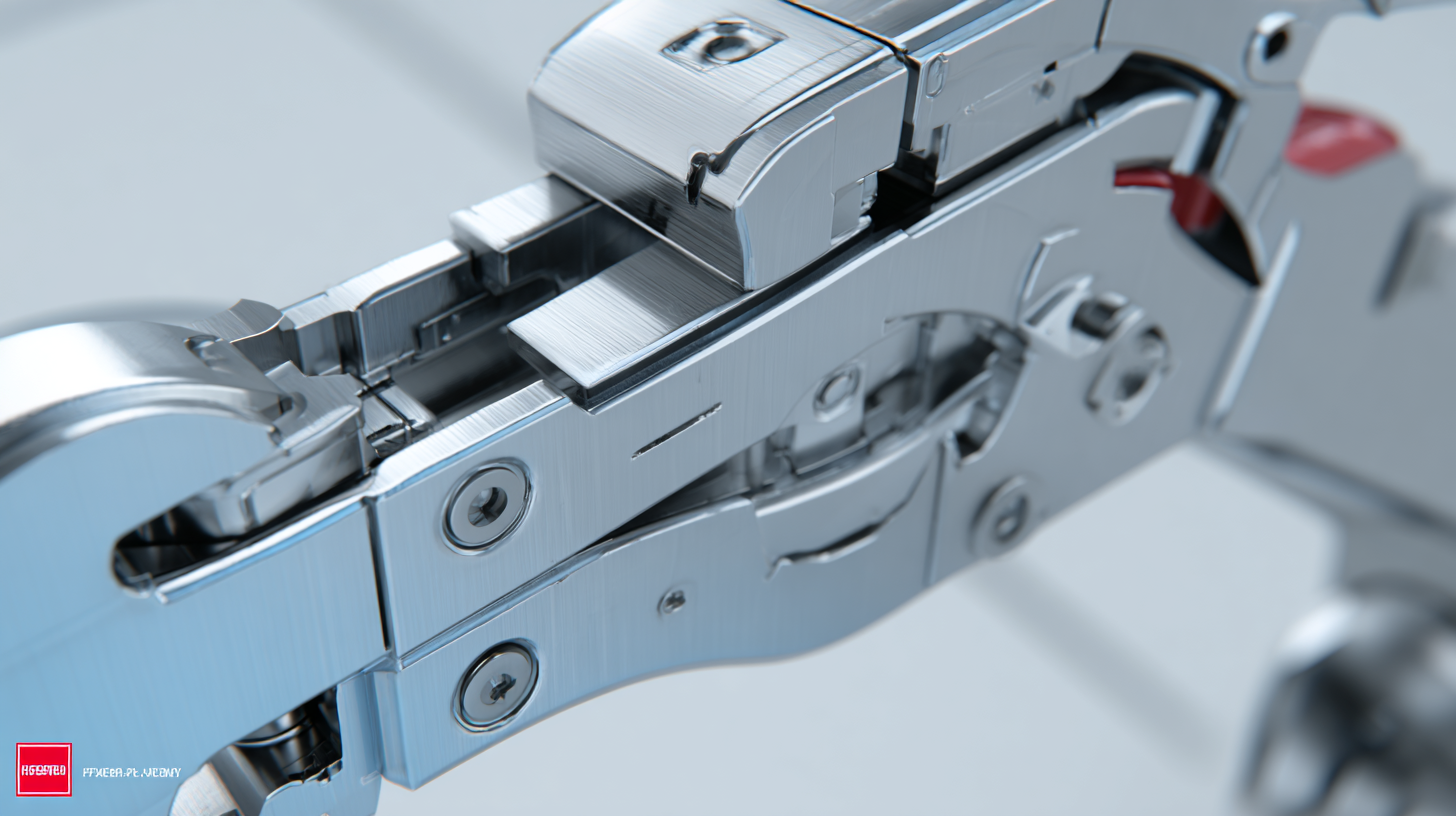

The punching tool industry is on the brink of transformation as innovations in technology revolutionize manufacturing processes. Advanced CNC punching machines have gained significant traction, with the global market projected to expand by 5% annually through 2025, surpassing $1 billion. These machines utilize precision programming and automation to enhance efficiency, minimizing material waste and optimizing operational costs. Reports from industry leaders highlight that companies adopting automation in their machining processes can see productivity increases of up to 50%.

Moreover, developments in materials science are leading to the integration of lightweight and durable materials in the production of punching tools. For instance, the use of composite materials not only improves tool longevity but also boosts performance by reducing fatigue during operation. A recent survey indicated that 68% of manufacturers are considering the adoption of such materials to enhance the durability and efficiency of their punching tools. As these trends continue to evolve, the industry is poised for a significant shift, characterized by increased precision, sustainability, and automation in production methodologies.

Top Punching Tool Types and Their Technical Specifications for Industry Leaders

As industries evolve, the demand for high-performance punching tools continues to rise, driving innovation and redefining operational standards. In 2025, industry leaders will see an increased focus on technological specifications that enhance precision and efficiency. According to a recent report by Market Research Future, the global punching tool market is projected to grow at a CAGR of 6.2% from 2023 to 2028, highlighting the necessity for tools that not only meet operational efficiency but also adapt to diverse material requirements.

Among the top punching tool types, hydraulic punches are gaining significant traction due to their superior force output and versatility. These tools often come with adjustable stroke lengths and can accommodate materials ranging from mild steel to aluminum.

Additionally, CNC punching machines offer unparalleled precision, allowing for complex designs to be executed with minimal waste. Reports suggest that the integration of smart technology in these machines, such as IoT connectivity and automated workflow systems, is expected to be a game-changer, boosting production rates by up to 30% while reducing downtime. As we approach 2025, the emphasis on sustainable practices will also prompt the development of eco-friendly punching tools, ensuring that both performance and environmental responsibility go hand in hand.

Data-Driven Insights: Market Growth Projections and Consumer Preferences

As we look ahead to 2025, the punching tool industry is experiencing significant transformations driven by data-driven insights. Recent market research indicates that the global punching tool market is projected to reach USD 4.5 billion by 2025, growing at a CAGR of 6.7%. This growth can be attributed to advancements in technology and an increasing demand for precision and efficiency in manufacturing processes. Notably, industries such as automotive and construction are leading the charge, with a marked preference for tools that offer enhanced durability and performance.

Consumer preferences are also evolving, with sustainability becoming a key driver in purchasing decisions. A recent survey revealed that over 70% of consumers prefer tools made from eco-friendly materials, indicating a shift towards environmentally conscious products. This trend is prompting manufacturers to innovate, incorporating sustainable practices and materials into their offerings. Furthermore, the integration of IoT and smart technology in punching tools is gaining traction, with approximately 40% of consumers expressing interest in smart tools that offer connectivity and data tracking for improved operational efficiency. These insights reflect a dynamic market landscape where consumer preferences and technological innovations interplay to shape the future of the punching tool industry.

Sustainability and Eco-Friendly Innovations in Punching Tool Design for 2025

As we look toward 2025, the punching tool industry is set to embrace significant sustainability and eco-friendly innovations. Manufacturers are increasingly recognizing the importance of adopting environmentally responsible practices not only to meet regulatory requirements but also to appeal to a growing customer base that prioritizes sustainability. Innovations in materials, such as the use of recycled metals and biodegradable composites, are emerging as key trends. These materials not only reduce environmental impact but also often enhance the durability and efficiency of the tools.

Additionally, advancements in energy-efficient manufacturing processes are gaining traction. By utilizing renewable energy sources and optimizing production techniques, companies can significantly cut down their carbon footprints. Companies are exploring the integration of digital technologies, such as IoT and advanced analytics, to monitor energy consumption and improve resource management throughout the production cycle. These eco-friendly innovations not only fulfill corporate social responsibilities but also pave the way for long-term cost savings, making the punching tool industry a leader in sustainable manufacturing practices.